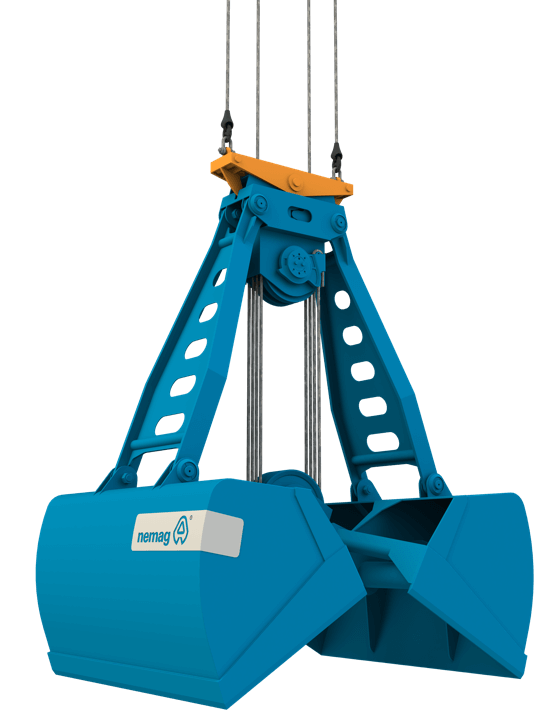

As a port operator, regular maintenance of your grabs is essential to ensure optimal performance, maintain productivity, and minimize downtime. However, with numerous responsibilities, maintenance can often be overlooked. When a grab breaks down unexpectedly, it will lead to substantial downtimes and consequential it will have impact on the lay time of the ship.

Grabs, though durable, endure varying degrees of wear depending on the materials handled. Components like shells and knives are in contact with bulk material and require regular maintenance. Neglected maintenance may lead to substantial costs and significant operational issues, which makes regular maintenance planning crucial. By investing in preventive maintenance and keeping essential spare parts on hand, operators can avoid these risks and ensure smooth, uninterrupted operations.

In this blog, we uncover the price of neglected maintenance and share advice to keep your grabs in top condition.

Table of contents

1. The costs of unplanned maintenance and downtime

2. Best practices for grab maintenance

3. The importance of stocking spare parts and choosing originals

4. Proactive maintenance: prevention is better than cure

5. Maintenance checklist to increase your operational reliability

The costs of unplanned maintenance and downtime

Regular maintenance of your grabs is a key factor to avoid the costs of unplanned maintenance and downtime. Without timely, preventive maintenance, several issues can arise.

A grab can start losing its load, causing bulk material to spill over the quay or fall into the water, resulting in expensive losses and environmental issues. A leaking grab cannot be used until it is repaired, which can result in several days of downtime in case there is no redundancy in the grabs.

If a breakdown occurs while a ship is being loaded or unloaded, it can bring the entire operation to a standstill. You would need to find a replacement grab quickly or face significant delays. In the case of transshipment, delays are even longer due to the lack of infrastructure to rapidly get materials and/or engineers on board. Besides the cost of lost productivity and the work and materials needed for repairs, downtime can also incur demurrage charges. Demurrage rates for bulk carriers can range from $10,000 to $20,000 per day: the impact of downtime on demurrage is not to be underestimated.

Best practices for grab maintenance

The best strategy for avoiding costly downtimes and ensuring the longevity of your grabs is regular lubrication, which is generally heavily underestimated. This should be a disciplined part of your maintenance routine as it reduces wear on points of rotation and extends the grab’s lifespan.

Nemag grabs are equipped with a centralized greasing system, making this task easier and safer. This system allows fast and simple greasing of all moving parts and eliminates the need for dangerous climbing. More information on the type of grease and the recommended lubrication frequency can be found in your operation and maintenance manual.

Figure 1 - Centralized greasing system

In addition to lubrication, other types of proactive maintenance are crucial, such as checking and replacing closing and hoisting wires, inspecting pivot points, and ensuring the integrity of cables and guides and visual inspection for cracks in the grab structure. The frequency and type of maintenance required depend on the bulk material being handled; for example, handling wheat may primarily require lubrication, while more abrasive materials like iron ore necessitate extensive upkeep.

Because spare parts often have a delivery time, maintaining a stockpile for unexpected situations is essential. Having essential spare parts readily available ensures prompt issue resolution and helps avoid extended downtimes.

While proactive maintenance can address common wear and tear, human errors can lead to severe damage to components like pivot points, cables and wire guides. These errors can result in sudden failures and extended downtimes, amplifying the operational and financial impact.

In short, investing in preventive maintenance and keeping essential spare parts on hand, is a very small cost compared to the significant expenses of unexpected/unnecessary downtimes and repairs, shutting down the entire operation.

The importance of stocking spare parts and choosing originals

Having spare parts in stock is essential to maintaining operational continuity and avoiding costly downtime. Wear and tear, or even operator errors, can cause grab failures that necessitate immediate repairs. Without readily available parts, a minor issue could halt operations for days, sometimes costing tenfold or even a hundredfold more than the parts themselves. Investing in spare parts is an investment in operational security, much like an insurance policy that prevents expensive disruptions.

Some companies hesitate to invest in spare parts, seeing it as an unnecessary expense. However, the consequences of not having critical components readily available far outweigh the initial costs. Therefore we support a healthy maintenance policy by offering reduced pricing on spare part bundles in the case of a grab purchase. Investing in spare parts is also investing in operational reliability.

What’s the benefit of using original spare parts versus third-party parts?

Original parts ensure quality and reliability. They meet the original standards and will have the longest lifespan, leading to lower risks and less frequent replacements. Additionally, modifying non-original parts to fit takes more time, increases downtime, and can potentially shorten their already inferior lifespan even further: hence investing in original parts is always the best.

Standardized components from Nemag are designed for durability and reliability. Ensuring you have a stock of these essential parts mitigates risks and keeps your operations running smoothly. Always choose original parts to guarantee quality and performance, and avoid the pitfalls of using inferior, imitation parts.

Nemag strives to use grab components, such as bearings and plate materials, that are internationally standardized and widely available, allowing you to source replacement parts locally without hassle. Ensuring you have a stock of these essential parts mitigates risks and keeps your operations running smoothly. Always choose original parts to guarantee quality and performance, and avoid the pitfalls of using inferior, third-party parts.

Proactive maintenance: prevention is better than cure

In conclusion, regular maintenance of your grabs is crucial for optimal performance, productivity, and minimizing downtime. Key practices include disciplined lubrication, proactive maintenance checks, and having essential spare parts on hand. Regular lubrication, facilitated by Nemag’s centralized greasing system, significantly reduces wear and extends the lifespan of your grabs.

Investing in original spare parts ensures reliability and prevents costly disruptions. Neglecting maintenance or using inferior parts can lead to substantial operational and financial impacts.

Want to know the best maintenance strategy for your specific situation?

Feel free to contact us if you have any questions. In a free consultative call, we will provide tailored advice to ensure your grabs operate at peak performance to reduce downtime and avoid costly disruptions.

Extra: Maintenance checklist to increase your operational reliability

1. Read the manual: Start by thoroughly reading the Operation and Maintenance Manual. This manual contains:

-

- Descriptions and overview

- Safety

- Installation

- Operation

- Appendices (drawings, forms, inspections, additional datasheets)

- Maintenance schedules

- Maintenance procedures

- Transport and storage

- Technical data

- Troubleshooting

2. Follow maintenance and operating instructions: Adhere to guidelines (for example, lubrication and maintenance frequency).

3. Lubrication: Regular lubrication is the best preventive maintenance.

4. Monitor your grab: Visually inspect and listen for unusual sounds. Address issues immediately.

5. Stock spare parts: Always have spare parts available to prevent costly downtime. Unforeseen delays can extend delivery times.

Implementing these practices ensures your grabs operate efficiently and reduces the risk of expensive disruptions. For more information, consult your manual or contact Nemag for support.