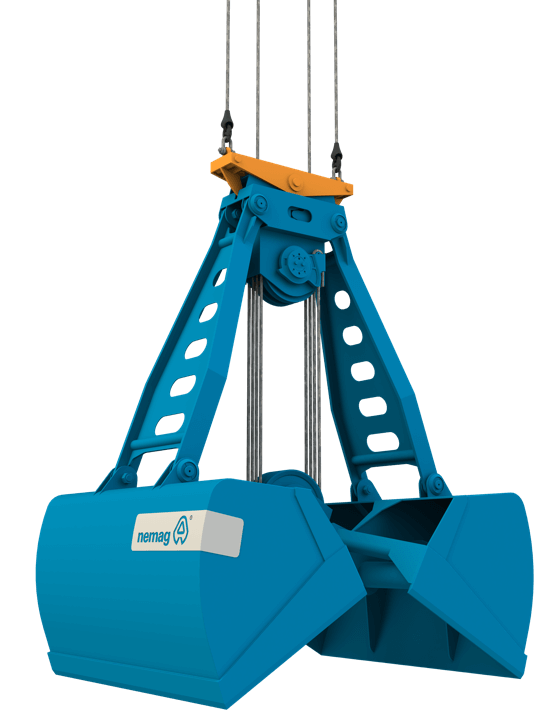

Dry bulk terminal operators are always looking for ways to increase terminal efficiency. It’s also important to optimise profits for shareholders and to increase the competitive edge. Grabs are extremely decisive for terminal efficiency. That’s why Nemag introduces the most productive grab for iron ore: the NemaX®. This new grab for handling iron ore will increase productivity by more than 10%.

The dry bulk terminal operator environment is changing rapidly. There is extreme pressure on handling rates because of the overcapacity in the dry bulk market. This creates a growing concern among shareholders to increase yields from their investments. At the same time costs for wages, maintenance and energy are rising.

An innovative solution

Existing infrastructure

The cheapest way to increase productivity

The productivity of a grab unloader is the product of the grab’s payload times cycles per hour. The productivity is also determined by the speed of the crane, travel distances and the opening and closing time of the grab. The basic crane configuration cannot be upgraded without very costly modifications. By far the easiest and most cost-effective solution is to exchange the grab for an efficient one.

The lowest deadweight combined with speed of closing and opening are of paramount importance, and that’s exactly what Nemag’s new grab offers. Through exhaustive computer simulations, Nemag has succeeded in developing a new generation of – patented – grabs for handling iron: the NemaX® grab. Using the NemaX grab will increase the productivity performance of the entire installation by at least 10%.

"We unload a ship in four days instead of five"

Paulo Ribeiro, Spec. Port. Operations Technician at VLI Pecém even experienced a 20% productivity increase. They bought three different grabs to finally unlock this productivity gain. Read the full case study of this Brazilian logistics company.

Want to know what the NemaX would mean for your productivity?

Try the NemaX compare tool to compare your current grab to the NemaX or download the quick guide to learn more about this productivity increasing grab.