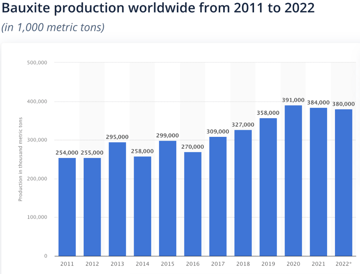

Bauxite is one of the five major bulk commodities, primarily used for the production of aluminium as well as the rare metal gallium. In 2022, the global production of bauxite marked a total of approximately 380 million metric tons. Australia, China and Guinea were the biggest bauxite-producing countries. Australia, as the world’s largest producer of bauxite, produced an estimated amount of 100 million metric tons, whereas China and Guinea produced 90 and 86 million metric tons of bauxite. Guinea has the largest bauxite reserves in the world, with approximately 7.4 billion metric tons as of 2022 according to Statista.

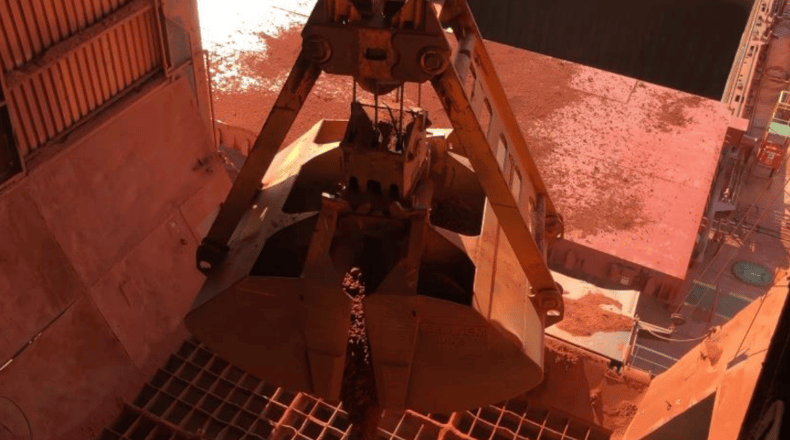

Bauxite has mainly three different appearances:

1. Pelletized bauxite (e.g. Weipa bauxite)

2. Wet and clay-like bauxite with inclusions of stones (e.g. Kamsar / Trombetas)

3. Dry and earthy-like bauxite with inclusions of stones (e.g. Kamsar / Trombetas)

The best choice of grabs for different conditions

Selecting the appropriate grab for the right type of bauxite, considering its appearance, density, and moisture content, is crucial for terminal operators. This selection is key to prevent overloading the installation and to enhance overall terminal performance. The choice for the ideal grab also requires a good understanding of the prevailing conditions:

- Unloading with shore-based cranes or floating transshipment?

- Size of the ship: barge or bigger vessel?

- Type of crane

The primary challenge involves identifying the optimal grab solution and unloading procedure to maximize average unloading performance. Additionally, it's important to assess the influence of the grab type on the costs of auxiliary equipment, like trimming tools and staffing, as well as the maintenance expenses associated with these operations.

The best grab for pelletized bauxite

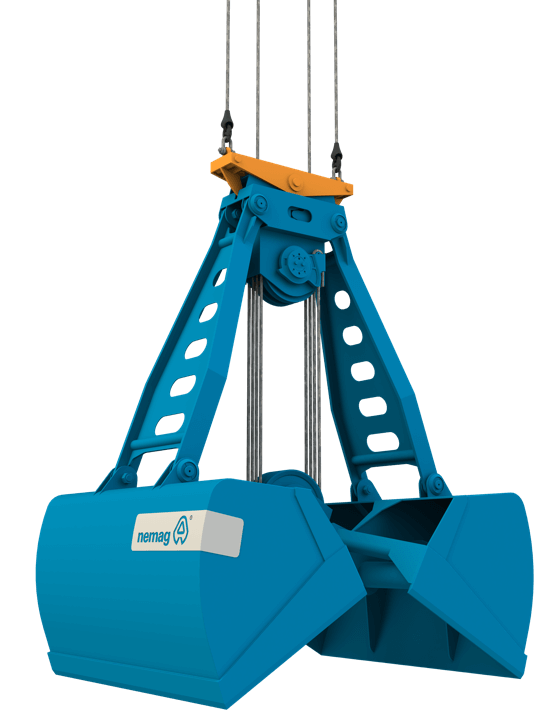

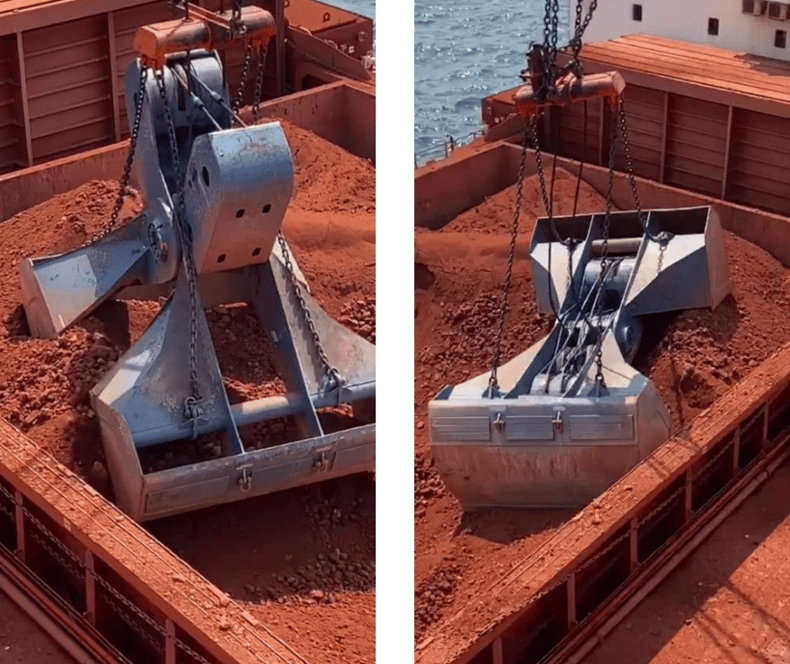

The best choice to unload pelletized bauxite is a lightweight clamshell or a NemaX grab.

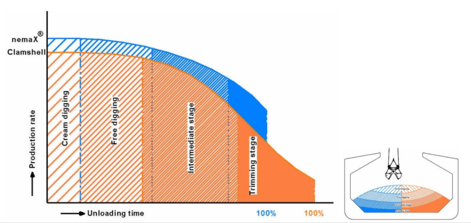

The NemaX would be the preferred choice for handling pelletized bauxite, as it offers:

- At least 10% higher performance compared to lightweight clamshell grabs;

- At least 10% savings on energy costs per ton of material transferred (energy savings alone is a very decisive factor in the ROI, this apart from higher productivity);

- lowest maintenance costs;

- long life span of the closing ropes.

Furthermore, NemaX enables an enhanced free digging phase and shorter cleaning-up times because of a large footprint and horizontal closing motion, hence reducing the use of trimming equipment and reducing staff in the hatch improved safety.

The best grab for dry and wet bauxite with inclusions of stone

Presently, the handling of these types of bauxite is typically done using either a clamshell or a trimming grab. However, each of these grabs has its own disadvantages.

In a direct transshipment scenario, where the cargo is transported to the Floating Transfer Station in barges carrying a relatively thin layer of cargo in the hold, challenges arise with the use of a clamshell type of grab. The design of the clamshell grab, which requires vertical movement within the cargo to fill, becomes less efficient in this context, ultimately leading to a reduced productivity.

In fact, in such situation of barges one could say that there is only a ‘cleaning up phase’.

In such situations, a trimming grab could be a more suitable option. Its horizontal closing curve is better suited for cleaning up and is ideal for working within a thin layer of cargo.

The better option for this specific application is the better and more economical alternative for the trimming grab; the Nemag Scissors grab.

A scissors grab has the very same handling characteristics of the trimming grab:

- Similar payload and deadweight;

- A big foot print;

- Low centre of gravity;

- Very good digging performance in coarse materials.

However, the scissors grab has important advantages in comparison with the trimming grab:

- A scissors grab has a shorter opening and closing time, so more cycles per hour;

- The rotational point is positioned in the centre of the grab, hence avoiding high torsional stresses like in a trimming grab;

- The open/close ropes of a scissors grab are not in contact with the abrasive bauxite:

this means no wear and tear to the ropes and significant higher lifespan of the opening/closing ropes. At a trimming grab the closing ropes and sheaves are continuously immersed in the bauxite causing excessive wear and tear on ropes and closing pulleys, with high maintenance costs as a result. - Significant lower wear and tear in the area of the opening/closing mechanism and pulleys in the grab, compared to a trimming grab.

In short:

- A scissors grab has same perfect digging characteristics as a trimming grab;

- is faster hence more cycles and productivity;

- has a significant better life span of the closing ropes;

- and has significant less damage to open/close pulleys.

Bauxite terminal operators experience 2 to 2,3 times lower OPEX costs of a scissors grab compared to a trimming grab.

Are you curious about which grab is the best boost for your bauxite boarding?

We have experience in handling bauxite and are happy to inform you on available solutions for your specific situation. For instance, SMT Shipping unlocked a 25% productivity increase by getting the right grab for the right job, which paid itself over four times back in just the first year.

Feel free to contact us or book a meeting to receive a free consultative call to find the best grab type for your application to boost your loading and unloading productivity.