The added value of the scissors grab

- Favourable volume in relation to its own weight

- Extremely robust design

- Application of wear-resistant and high-tensile steel

Reliable and fast handling of your dry bulk materials

The Scissors grab has a high average productivity thanks to its fast opening and closing mechanism and short cycle times. The scissors grab also performs excellently on sloping surfaces, reducing your need for trimming equipment and staff.

"In terms of unloading performance and reliability, we are using the best type of grab available."

- Mathew Cunningham, Maintenance Manager at ESB Power generation, moving 2 million Tonnes of coal annually.

"Nemag thinks and works innovative. We have a low grabdead-weight and low maintenance-costs due to their expertise. I recommend Nemag."

- S.W.A. Lak, Managing director at EMO, moving 33 million Tonnes of ores and coal annually.

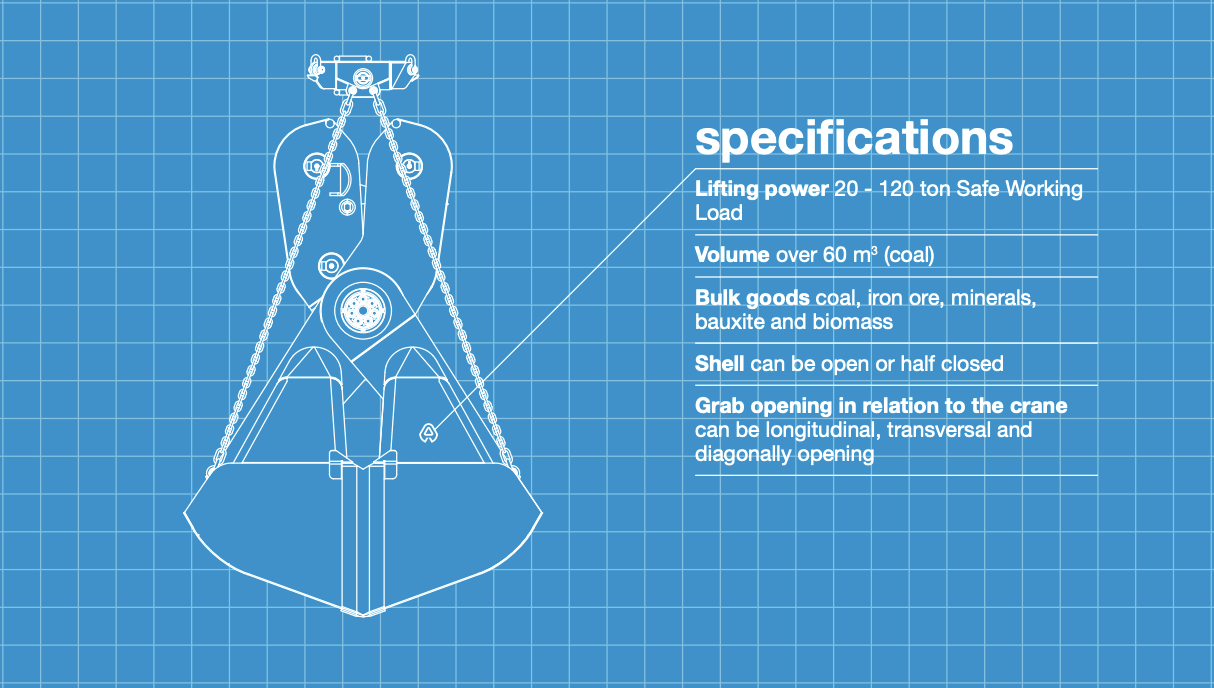

Scissors grabs can be customized to optimize your installation and are available with a safe working load up to 120 ton. And the volume range can be more than 60 m3. Scissors grabs are available with an open or half-closed shell. The grab opening in relation to the crane can be longitudinal, transversal and diagonally opening.

Download the Scissors Grab product brochure for more information about its applicability. Additionally you can learn about our service and maintenance or leadership in quality. Feel free to schedule a meeting or contact us us if you have any questions.

|

Wear-resistant and high tensile steel

|

Short delivery times and enhanced ease of maintenance | Shorter Cleaning Up phase due to large footprint and high stability |

| Safer and more efficient due to low point of gravity | Option for radiation detection on scrap grabs | Automatic central lubrication system |

All Nemag products are highly customizable modular grabs. We fit and optimize the grab to your specific situation. The Scissors grab is best available for the following bulk materials:

Download the brochure for more information on the Nemag Scissors Grab. Can't find the information you are looking for? Contact us or schedule a meeting.

You can improve your acceleration with...

...%

We have sent you an e-mail with a more detailed report

To calculate your productivity increase we need additional information. As we’re not familiar with your current installation. Please share your email address for us to contact you.

We will get back to you as soon as possible

Crane capacityIs the Safe Working Load of your crane in tons in grab duty, i.e. the total sum of grab dead weight and payload.

PayloadIs the nett load of cargo in the grab. Because it’s linked with the grab weight it will be filled in automatically.

Grab weightIs the Dead weight of your existing grab. Not sure? Check your grab manual, CE declaration, or on the ID plate on your grab.

Grab rope withdrawal lengthIs the length of the closing rope which needs to be pulled out in order to close the grab (not to confuse with the total reeved in grab rope length).

Not sure about the numbers?Check the grab manual. Don’t hesitate to contact us.

+31 (0)653109307